As the word implies, Direct Materials Quantity Variance refers to the deviation resulting from the difference in the expected and actual quantity of direct materials used by a company in production. Although this variance is of the quantity, we express it in dollars. We also call it direct material usage or volume variance.

In general, this variance indicates whether the company uses the direct materials correctly or not. So the lower the variance, the better it is. To reduce the variance, it is important to improve efficiency. One way to do this is to reduce the wastage of raw materials.

Similar to the DM quantity variance, there is a DM price variance. Here, the variance is due to the price. The DM Price Variance is the result of the difference between the price of the direct material and the standard price assumed at budgeting. The price actually paid could be lower or higher than the standard price.

Favorable or Unfavorable Direct Materials Quantity Variance

The DM quantity variation could be either favorable or unfavorable.

A favorable variance is when the actual quantity that a company uses is less than the standard quantity. This means that the company is able to save direct materials at the time of production. A favorable variance could imply that the workers or the production process are efficient.

Also Read: Material Variance

However, it can also mean that the company or the production department deteriorates the product quality by using less material, and this deterioration leads to direct material savings.

On the other hand, an unfavorable variance is when a company uses more than the standard quantity, which means that it uses more materials in production than it should.

An unfavorable variance could be due to the hiring of less skilled people to save labor costs. It could also be due to the use of inferior material, which means that more materials are used to form a unit.

A favorable variance has a positive effect on the operating result of the company. On the other hand, an unfavorable variance negatively affects the operating result. It is already part of the income statement in the accounting of variances. If a company follows a standard cost system, it credits the favorable variances and debits unfavorable variances.

Formula and Example

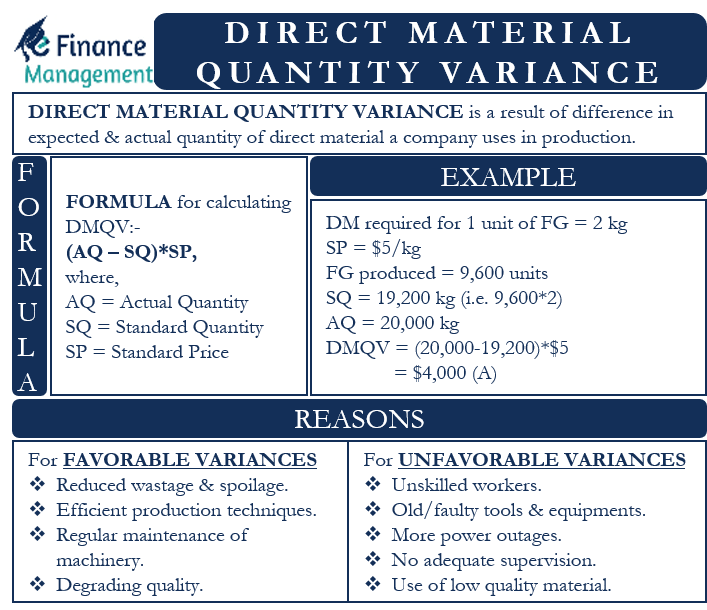

To calculate the DM quantity variance, we have to subtract the actual quantity from the standard or expected quantity and then multiply the resulting number by the standard price.

Formula for DM quantity variance = (AQ – SQ) x SP

Here AQ is the actual quantity, SQ is the standard quantity, and SP is the standard price.

Let us take an example to get a good understanding of the concept of DM quantity variance.

Company A produces bread and knows that 2 kg of wheat is needed for a unit of bread. Wheat is priced at 5 dollars per kg. However, last month, Company A discovered that it uses 20,000 kg of wheat to produce 9,600 units.

In this case, the AQ is 20,000, while the SQ is 19,200, and SP is $5.

So, DM quantity variance will therefore be = (20,000 – 19,200) x $5 or $4,000 unfavorable.

This variance is unfavorable because more wheat is used than the company should.

Reasons for Direct Material Quantity Variance

The following are some of the reasons that may result in the DM quantity variance (unfavorable):

- Inexperienced workers or lack of training for workers

- No motivation for workers to be efficient

- When there is no proper supervision

- If the machines, tools, and equipment are old or defective.

- Purchase of inferior materials.

- When the factory faces many power outages.

The following are some of the reasons that may result in the DM quantity variance (favorable):

- Use of high-quality materials

- Reducing wastage and spoilage

- Use of more efficient production techniques

- Regular maintenance of machines and equipment

Final Words

Direct Materials Quantity Variance in the quantity of materials is generally not good for a company or a department. Typically, DM quantity variance is the responsibility of the production department, as it has direct control over the raw materials. This variance can also be indirectly influenced by other departments besides the production department, such as the purchasing department for purchasing inferior materials. In the event of a variance, management must therefore conduct an appropriate analysis to determine the cause of the variance. And then take appropriate measures to reduce or eliminate it.

Read Material Variance for more details on other types of material variances.

RELATED POSTS

- Material Yield Variance – Meaning, Formula, Example, and More

- Production Volume Variance: Meaning, Formula, Limitations, and More

- Cost Variance – Meaning, Importance, Calculation and More

- Variance Analysis Formula with Example

- Material Mix Variance – Meaning, Example, and More

- Sales Quantity Variance