What do we Understand by a Unit Price Contract?

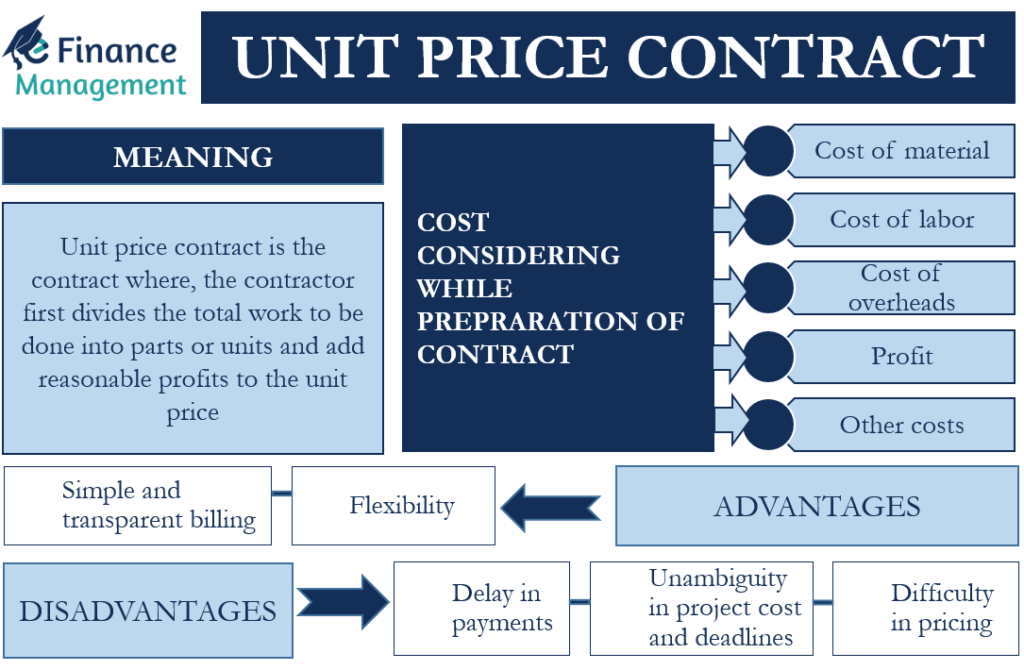

A Unit Price Contract is a popular form of contract with maximum use in the field of public construction works. We also call them “measurement contracts,” “remeasurement contracts,” or “measure and pay contracts”. Contractors use such contracts when the proposed scope of work is unclear and uncertain. The scope and quantum of work can vary either way during the execution stage of the contract itself. Usually, it encounters an increase in scope.

The work can increase mid-way during the project time- and- again as per the requirements. Due to this reason, preparing an exact estimate and quoting the overall project price becomes impossible. Also, the increase in the scope of work usually involves the repetition of activities already performed during the course of the project or something similar to it. This makes doing the pricing of the additional work easy. The contractor can easily charge for them on the basis of the earlier estimates that have been passed for the project.

In a Unit price contract, the contractor first divides the total work to be done into parts or “units.” He then prepares a pricing estimate for each of the units. The pricing depends upon the quantity of material used, overhead expenditures, labor charges, his share of profits, etc. The party that is getting the work done gets an estimate of the total cost of the work. In case it increases any unit or portion of the work, the contractor can simply add the price of that particular unit or unit to the total bill. There are little or negligible chances of a dispute arising out of pricing concerns later on because the rates have already been passed at the time of the finalization of the contract. Thus, it is advantageous for both parties to the contract.

What are the Costs to Consider while Preparing a Unit Price Contract?

Cost of Material

This is the foremost and easiest component to calculate the cost in such contracts. The contractor should prepare a correct estimate of the total material cost that he will incur for every unit of the project. Also, he should make appropriate provisions for wastages too so that he does not incur any loss due to inappropriate estimation later on. He should also take care of any increase or decrease he is expecting during the implementation period of the contract. Especially when the execution period is long enough.

Also Read: Estimation of Project Cost

Cost of Labor

After material, the biggest cost in any project is that of labor. The contractor should prepare an extensive list of all the skilled, semi-skilled, and unskilled workers that he will require for the project. He will then have to divide their roles and properly allocate and charge them for each of the units. Labor here can include supervisors, architects, equipment and machine operators, artisans and manual labor, etc. Also, he will have to properly allocate their costs on the basis of their salaries and hourly rates.

Cost of Overheads

Correct estimation and allocation of overhead costs can be a bit difficult for any contractor. Such costs may include rent, utility bills, miscellaneous supplies, fuel costs, insurance, transportation and logistics, taxes, etc.

Other Costs

Often, contractors in a big project sublet their work to other smaller contractors. Hence, costs pertaining to such partners in work have to be taken into account. Also, there may be a myriad of unexpected costs that may arise later on in any project. Inspection costs, the cost of permits and licenses, etc., can come up, and their correct estimation can be very challenging. Hence, contractors usually include a percentage as contingency cost.

Profit

This is the most important portion of pricing for any contractor as it is his driving force and reason for taking up the contract. The contractor needs to keep a realistic and fair amount of profits for himself. He can either mark a percentage of total costs as his profits or may charge a fixed fee. Like other costs, this portion also needs to be allocated to the various segments and units of the project for equitable distribution. And thus to arrive at the final per-unit cost.

What are the Advantages of a Unit Price Contract?

Simple and Transparent Billing

A Unit price contract keeps the billing process simple, transparent, and free of any ambiguity. The rates for every respective unit or portion of work are fixed at the onset of the project. Both the parties to the contract are clear of the total bill to expect as per the scope of the work. There remains no chance for dispute with regard to the cost of the extra work.

Flexibility

A Unit price contract offers immense flexibility during the course of the project. Since these projects may last over several years, the additional need for work may come up at a later stage after the initial planning. It allows adding or expanding the project mid-way, which can be very helpful to the project planning and implementation team.

What are the Disadvantages of a Unit Price Contract?

Unambiguity in Project Cost and Deadlines

The project cost to expect in a Unit price contract is unambiguous. The scope of the work can change later on. Hence, budgeting for a project becomes difficult and may consume more financial resources of a company than expected at the beginning. It calls for a lot of paperwork, too, to exactly measure and verifies the actual work done.

Also, since these contracts allow for an increase in the scope of work at a later stage, the deadlines to be met often become unclear. The contractor is not clear about the exact time when he and his resources will get free from a particular project. This hampers his planning to take up a new project and allocate his resources elsewhere.

Delay in Payments

Many times contractors face the problem of delay in their due payments. Remeasurement or adding up units to work is a time taking process. Its planning and approval may delay the entire project. This will eventually delay the payment of the contractor.

Difficulty in Pricing

Correct estimation and pricing of each unit of work is a very challenging process for any contractor. The basic components of the cost may undergo change as per the changes in the scope of work or units. This makes it difficult to arrive at the correct cost of units later on when additional units get added to the project.

What Happens if the Costing Increases Mid-Way During a Unit price Contract?

As discussed above, a contractor prepares an estimate of all the costs he might incur for every unit of work. Then adds his profit to it and gives the total price for each of the units. But what if the total cost of the project increases during the tenure of the project? The projects of public construction works are big such as the construction of highways, bridges, setting up of new railway lines, etc. They may take several years to complete. Thus, the unit price that was fixed at the beginning of the contract may become obsolete and irrelevant after a few years due to the effect of price increases and inflation.

In order to protect the interests of the contractor, government departments such as the Railways offer a “Price Variation” clause in the contract. The contractor can claim the variation or difference in the current price of the inputs and his estimated price at the beginning of the project. This variation is sanctioned according to the price variation index that is regularly updated by the governing authorities. Thus, this clause safeguards the interests of the contractor. Such a clause also gives clarity about how the costs will be worked and limit the dispute with regard to price increase and total cost. The contractor is also saved and remains free from the risk of price variation.

Also, read Lump-Sum Contract Vs. Unit Price Contract for more.

RELATED POSTS

- Cost Plus Contract: Meaning, Types, Advantages, Example, and More

- Incentive Contract: Meaning, Types, Advantages, Disadvantages and More

- Lump-Sum Contract: Meaning, Advantages, Disadvantages and More

- Job Costing – Meaning, Benefits, Process and More

- Budgeting in Project Management

- Cost Estimation Methods – All You Need To Know