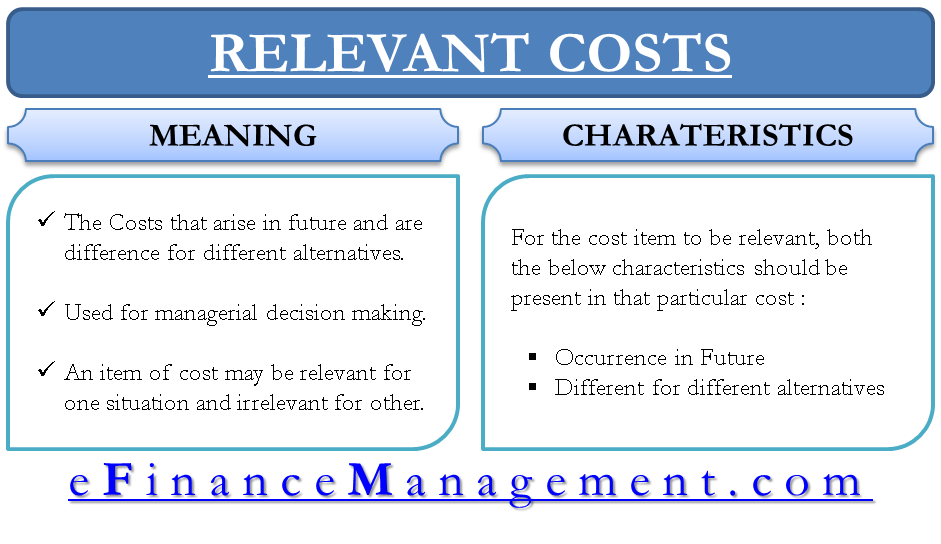

Relevant costs are defined as the costs that arise in the future and are different for different alternatives. The concept of relevant costs is used by management for making various decisions such as special or one-time order pricing, making or buy decisions, adding or dropping product lines, in-sourcing vs. outsourcing, etc. These costs are issue-specific. An item of the cost may be relevant for one situation and irrelevant for other.

Characteristics of Relevant Costs

Two important characteristic features of relevant costs are ‘Occurrence in Future’ and ‘Different for Different Alternatives.’ This does not mean that all costs which occur in the future are not relevant costs. For a cost, item to be relevant, both the conditions should be present. A future cost has also to be different from the alternatives, making it a relevant cost important for decision-making. In other words, the costs which do not change with the alternative situation are irrelevant costs not considered by management. Usually, sunk and future costs are irrelevant costs (not changing with alternatives under consideration). Relevant and irrelevant costs are mutually exclusive events. A cost item in one situation cannot be both relevant and irrelevant cost simultaneously.

Visit Relevant Cost vs. Irrelevant Cost

Relevant Cost Example

We will take an example of two alternatives, viz. ‘rearranging facility layout’ or ‘maintain status quo,’ to understand the relevant cost situation. Assume a company manufacturing scooters reorganizes its facility layout. The company has an advanced order book for the scooters. Therefore, whatever is produced is sold. The step of ‘reorganizing’ will increase production by 100 units from 1000 to 1100. It will also save the manufacturing labor cost by $100 per scooter. The cost of reorganizing is $150,000. The price of a scooter is $1200, the material cost per unit is $500, and the manufacturing labor cost is $400.

Apparently, the reorganizing looks profitable, but we have analyzed the situation in the following table. There are two approaches to analyzing the alternatives – All Costs and Relevant Costs. Both the approaches show the same result. Reorganizing is not a profitable move—the cost of reorganizing offsets both the increase in revenue and reduction in cost by $10,000.

| Particulars | Relevance for Decision Making | All Costs | Only Relevant Costs | ||

| Alternatives: | Status Quo | Reorganize | Status Quo | Reorganize | |

| Revenue (1000*1200) or (1100*1200) | Relevant | 12,00,000 | 13,20,000 | 12,00,000 | 13,20,000 |

| Material Cost @ $500 | Irrelevant | 5,00,000 | 5,50,000 | 5,00,000 | 5,50,000 |

| Manufacturing Labor @ $400 and $300 | Relevant | 4,00,000 | 3,30,000 | 4,00,000 | 3,30,000 |

| Fixed Overheads | Irrelevant | 75,000 | 75,000 | ||

| Reorganizing Cost | Relevant | 1,50,000 | 1,50,000 | ||

| Operating Income | 2,25,000 | 2,15,000 | 3,00,000 | 2,90,000 | |

| Difference in Alternatives | -10000 | -10000 | |||

Techniques for Analyzing Relevant Costs

Now, let us talk about two techniques of analyzing. Since the relevant cost technique only considers the relevant costs and relevant revenues, it simplifies the management decisions. Taking all the costs will complicate the situation, and focus will be lost between important and relevant costs and irrelevant costs. Deciding the relevance of a cost item is most important here.

A manager must take the precaution of two probable mistakes. Firstly, by mistake, irrelevant costs are taken as relevant costs. They will complicate the situation as well as increase the chance of faults. Secondly, the same unit costs of fixed manufacturing costs are taken for different activity levels. In our example, with the change in activity, the fixed overheads of $75,000 will change with change from 1000 units to 1100 units. They can hamper the whole calculation, and decisions relying on those will adversely affect the company’s profits.

See Types of Costs and their Basis of Classification for a more detailed article.