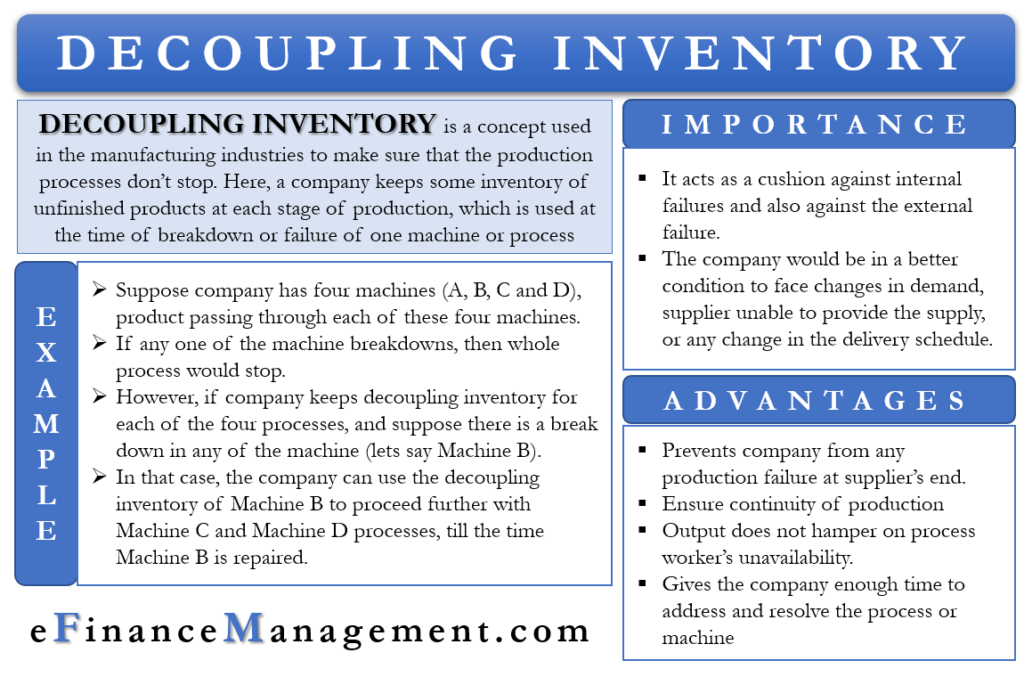

Decoupling inventory is a type of inventory that is of use to manufacturing firms. Moreover, this inventory comes in handy if the production processes are interdependent. In this, a company keeps some inventory of unfinished products at each stage of production. If there is a breakdown or failure of one machine or process, then the company uses decoupling inventory to make sure that the production processes don’t stop. In the meantime, the company fixes the issue with the machine or process.

Also, the concept of decoupling inventory works if a company offers different products that use at least one common raw material. For example, milk is a common ingredient for a company making cheese and ice creams.

Example of Decoupling Inventory

Let us consider an example to understand decoupling inventory better:

Suppose a company has four machines A, B, C, and D. The raw material passes through each of the machines to transform into a final product. It means that if any of the four machines breaks down, the whole manufacturing process will stop. Thus, to avoid this, the company maintains a decoupling inventory.

The company keeps additional stock of unfinished products for every stage of four machines, which means that it will maintain an inventory of the output from machine A, machine B, and machine C. In case of any of these machine breakdowns, the company will have extra inventory to feed to the next-in-line machines, and the production will continue.

Suppose machine A breaks down. In this case, the company will use the extra inventory of the output from machine A to continue the production. In the meantime, the floor manager will work to fix the issue with machine A.

Importance of Decoupling Inventory

Maintaining decoupling inventory becomes essential if a firm uses the same components in a multiple product mix or a product passes through different processes. In case of a breakdown, the company can divert the extra inventory to meet the more urgent orders.

On the other hand, if it does not have enough inventories for less urgent orders, then it can stop the work on such orders. It will ensure that the company is at least able to fulfill the urgent orders and doesn’t lose those clients.

A point to note is that the decoupling inventory not only acts as a cushion against internal failures but also against external factors. If a company maintains decoupling stock, it would be in a better condition to face changes in demand, suppliers unable to provide the supply or any change in the delivery schedule.

Also Read: Types of Inventory / Stock

Suppose, in the above example of machines A, B, C, and D, machine B uses the output of machine A, as well as an extra input. If the supplier fails to provide this additional input in time, the whole production process stops. But, if the company maintains a decoupling stock, it can use it to continue the production.

Advantages

The following are the advantages of maintaining decoupling stock:

- It prevents the company and production facility from any issues at the suppliers’ end.

- It ensures that the production continues even if there is any breakdown at some stage of processing or machinery.

- This inventory can also help the company maintain the output even if the workers responsible for some process or machine are on leave or go on strike.

- This extra inventory gives the company enough time to address and resolve the process or machine.

- A company can also carry out routine maintenance work in stages without stopping production.

If we talk about the drawback, like with any other inventory, the decoupling stock also has a carrying cost. Also, a company could incur losses if it is unable to safely store this inventory. However, maintaining decoupling stock has become a necessity for a company to avoid production interruption. So, the company needs to maintain a balance to ensure it does not spend too much on carrying costs and, at the same time, does not store too little to miss on potential opportunities or take care of frequent breakdowns, etc.

Decoupling Stock vs. Pipeline Inventory

Pipeline inventory is also the extra stock of raw materials that a company has. But, it is very different from the decoupling stock. Pipeline inventory includes raw materials and components that the company has already ordered but is yet to arrive. A company maintains a pipeline inventory if the parts or raw material take a significant time to come.

If we talk about the differences between the two, the decoupling stock is an internal mechanism, while the pipeline is an external mechanism. Maintaining decoupling stock helps to overcome bottlenecks, while pipeline stock is part of the procurement process.

Another difference is that the company maintains decoupling stock within its premise. On the other hand, the pipeline inventory exists in transit or outside the company’s premises. The decoupling stock is primarily maintained by companies that produce many products and have several production processes. Moreover, companies that use external parts or products between the processes. On the other hand, the pipeline system is common among companies whose raw materials or components take significant time to arrive. It is to make continuous availability of raw materials. And a reduction in the procurement lead time without incurring any carrying costs.

Read more on various Other Types of Inventories.

Final Words

So, we now know that maintaining a decoupling inventory is very important for a manufacturing concern with various stages in its production cycle. However, as with any other inventory method, deciding the right amount of decoupling stock is also challenging. But, if the company has a proper inventory management system, the task of determining the decoupling stock gets relatively easier.