Meaning

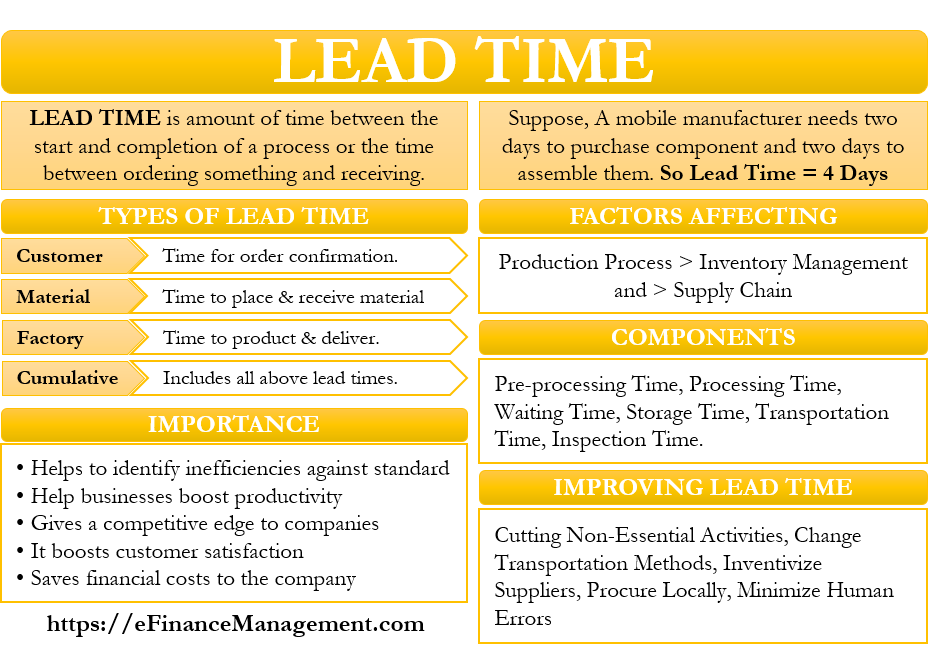

Lead time is an essential concept for a manufacturing organization. It is the amount of time between the start and completion of a process or the time between ordering something and receiving it. It is a common term in supply chain management and project management.

For example, Company ABC manufactures mobiles. It takes the company two days to get the components for making mobiles and two days more to assemble 500 units. We can say that Company ABC’s lead time to produce 500 units in four days. Any retailer or wholesaler should give ABC at least four days. It means that if a retailer needs the mobiles on 11th July, then they should place the order on or before 7th July.

Usually, the lower the lead time, the better it is for the company. It indicates that a business can quickly respond to any changes. However, lower lead times may not always be beneficial to the buyer as it could be the result of more shipping costs. Thus, shortening lead times may not always result in more profits, but it does improve customer satisfaction.

Types of Lead Time

Following are the types of lead times:

Customer

It represents the time that a company takes from receiving a confirmation for order until its fulfillment.

Material

It represents the time it takes to place an order with a supplier and receive supplies.

Factory/Production

It is the time that a company takes to produce and deliver the products if all the raw materials are available.

Cumulative

It includes all the above lead times. Or, we can say it is the time that a company takes from receiving a confirmation for an order to delivering the product to the customer.

Importance of Lead Time

The following points reflect the importance of lead times:

- Comparing lead times against the set standards could help a business identify inefficiencies, if any.

- Shortening lead times can help businesses boost productivity and restructure operations.

- It also gives a company a competitive edge over rivals.

- A quick turnaround helps to boost customer satisfaction.

- A quick turnaround also saves financial costs in terms of the blockage of lesser working capital.

- Lower shelf-life goods need lower lead time.

Factors Affecting Lead Time

Three main factors affect lead times:

Production Processes

The kind of production process a company adopts plays a significant role in determining the lead time for a product. For instance, completing the product on-site may take more time than doing it off-site. It is because transportation issues may delay the delivery of specific components. Also, locally sourced parts and labor and off-site sub-assemblies can help to reduce lead times.

Inventory Management

If a company can manage its inventory efficiently, it will ensure a smooth production flow. In the case of stock-outs or unavailability of specific components, the whole production goes on hold. Also, the production process may stop if a company fails to estimate the stock to complete an order accurately. Moreover, failure to replenish raw materials quickly could also increase the lead times.

All such things would impact the company’s bottom line. To overcome such situations, a company must have efficient inventory management. Several systems are available that can assist the management in managing its inventory efficiently. For instance, there is just-in-time (JIT) or VED inventory management, which places orders to the suppliers based on usage. (Read Inventory Management Techniques to learn more about various techniques).

Supply Chain

Lead times for a company will also depend on the number of suppliers it has. It is always challenging to estimate the delivery time from the suppliers accurately, and this, in turn, makes it difficult to coordinate production. Though a company could stock excess inventory, it raises the cost and leads to wastage as well.

To overcome this issue, a company can adopt a lead schedule. It assists the company in making arrangements so that necessary components arrive together. It not only reduces lead time but also shipping and receiving costs.

Also, it is a fact that a company can’t predict some delays, such as those happening due to natural disasters, human error, and other unexpected issues. However, to minimize losses due to such problems, a company should maintain a backup supplier to ensure production continues smoothly.

Components

Usually, the following activities go into deciding the lead times:

Pre-processing Time

It refers to the planning time. It includes the time to receive the request for replenishment, evaluate it, and develop a purchase order on its basis.

Processing Time

It includes the time to produce an item after receiving a purchase order.

Waiting Time

It is the time between procuring raw material to the time when the production starts.

Storage Time

It is time that the items remain in the warehouse or factory before the delivery.

Transportation Time

It is the delivery time or the amount of time a product takes to move from a factory or warehouse to the customer.

Inspection Time

It includes the time that a customer spends on inspecting the product or verifying if the product meets the specifications.

How to Improve Lead Times?

A company or a business can reduce lead times using the following measures

- Eliminating Non-essential Activities

A company must identify the activities that add value and those that don’t add any (or little) value. Eliminating activities that don’t add any value and those that the company can live without can help improve the lead times.

- Track Transportation Method

A company must continuously monitor various transportation methods. Over time, it could be possible that improvement in infrastructure could make an alternative shipping method much quicker.

- Provide Incentive or Charge Penalty

A company should offer a specific incentive to its suppliers, such as a bonus if they continuously deliver the items on time. Similarly, a company may also include a penalty clause in the supplier contact to ensure they stick to the agreed terms.

- Procure Locally

Buying raw materials locally and not from faraway suppliers is the quickest way to reduce lead times. However, the company must ensure that sourcing locally should not compromise the quality and cost.

- Strategic Changes

It means integrating the supply chain (if possible). For instance, a company manufactures and assembles products at two separate locations. Now, a company may combine the two processes at a single location. It would eliminate the transportation time in moving the product from one process to another.

- Minimizing Human-error

It is almost impossible to eliminate human error, but a company can minimize it by automating the processes. For instance, the company can deploy the Vendor-Managed Inventory (VMI) system or any other inventory management solution to reduce human intervention.

Lead Time vs Cycle Time

Both the concepts are similar as both measure the time a process takes from the start to the end. Cycle time, however, focuses on the time it takes for an internal process to start and end. On the other hand, lead time is usually the time it takes to complete a customer’s request.

Read a detailed article on Lead Time and Cycle Time.

Final Words

Lead time is a crucial metric for any business. It assists the company in predicting sales, making operations efficient, and improving customer satisfaction. However, it would be tough to improve lead times in the absence of a proper inventory management system, efficient production process, and right suppliers.

Read more on Takt Time vs Cycle Time.