What is Computer Integrated Manufacturing?

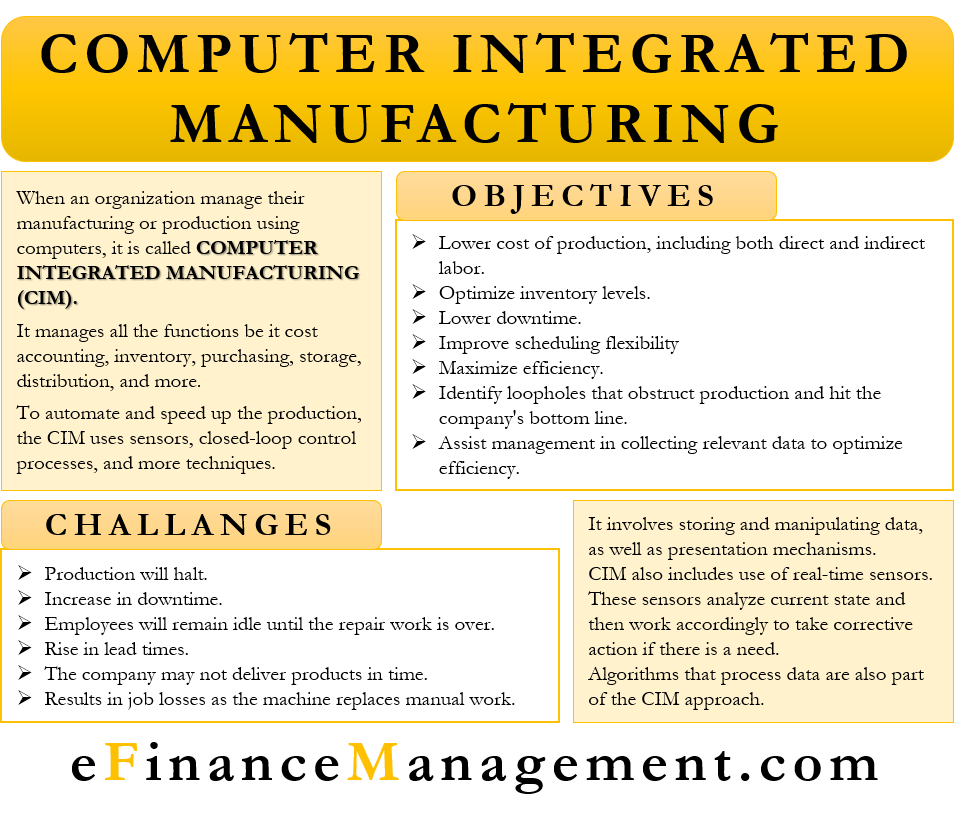

When an organization manages its manufacturing or production using computers, it is called Computer Integrated Manufacturing (CIM). In CIM, machines and automation systems control the whole manufacturing setup. We can say that companies use it to automate all its functions, be it cost accounting, inventory, purchasing, storage, distribution, and more. The use of computers for automation started after the 1970s.

CIM includes several computer-based technologies, such as CAD and CAM. The full form of these technologies is computer-aided design and computer-aided manufacturing. Other than CAD and CAM, CIM involves many more technologies, such as robotics, computer-aided engineering, EMS (enterprise management solutions), and more.

To automate and speed up the production, the CIM uses sensors, closed-loop control processes, and more techniques. All these technologies help minimize errors in manufacturing, lower dependence on manual labor and automate repetitive tasks. Companies in automotive, aviation, and space rely heavily on CIM.

Objectives of Computer Integrated Manufacturing

Following are the main objectives of using CIM:

- Lower the cost of production, including both direct and indirect labor.

- Optimize inventory levels.

- Lower the downtime.

- Improve the scheduling flexibility of a company.

- Maximize efficiency.

- Identify the loopholes that obstruct the production and hit the company’s bottom line.

- Assist the management in collecting relevant data to optimize efficiency.

Computer Integrated Manufacturing – What it Includes?

The following are the main components of CIM:

- It involves storing and manipulating data, as well as presentation mechanisms.

- CIM also includes the use of real-time sensors. These sensors analyze the current state and then work accordingly to take corrective action if there is a need.

- Algorithms that process data are also part of the CIM approach.

CIM – How it Helps?

Some of the popular processes that are part of the CIM approach are:

- Manufacturing of a prototype.

- Coming up with the best way to produce a product. For this, the CIM analyzes the cost, production methods, quantity, processes, and storage.

- It also automates the ordering of raw materials to ensure that the manufacturing process doesn’t stop.

- It also involves the use of computer numerical controllers for computer-aided manufacturing.

- CIM also helps a company to ensure quality control at each stage of production.

- It also helps in assembling the products using robots.

- CIM also automates the storage of products and the distribution of products from the storehouses.

- It also helps with updating financial numbers, logs, and invoices on the computers.

Example

One earliest example of automation is telephone switching. These switching machines made their debut towards around the 19th-century end. They were simple machines controlled remotely by a telephone user, either by pushing the buttons or turning the dial on the phone.

In modern times, telephone switching systems perform various functions, such as storing telephone numbers, monitoring the telephone lines, sending electrical signals, and more.

Computer Integrated Manufacturing – Challenges

Computers are machines, and machines could malfunction. So, the challenges for the company will increase with the increase in time the computer remains un-operational. Based on this, the following are the challenges that a company faces if CIM fails:

- Production will halt.

- Increase in downtime.

- Employees will remain idle until the repair work is over.

- Rise in lead times.

- The company may not deliver products in time, resulting in customer dissatisfaction and damage to its reputation.

- Unable to timely fulfill customers’ orders leads to loss of revenue, market share, and reliability.

- To properly implement computer-integrated manufacturing, a company needs a qualified and skilled staff and manager. In their absence, CMI may fail to give 100% results.

- Another challenge that CMI faces is that it results in job losses as the machine replaces manual work.

Final Words

Companies nowadays depend heavily on computer-integrated manufacturing. Over the years, many of its initial issues have been resolved, and those technological advances are now incorporated. Firms use the CIM in almost every department, be it engineering, mechanical or electronic design. Such an approach helps a company to boost efficiency and productivity, as well as reduce errors. It eventually assists the company in lowering its cost of production and quality and ensuring timely deliveries. Please note that automation at every stage is a keyword to save time, cost, and effort.