MRO Inventory means maintenance, repair, and operations inventory. It includes an inventory of all items that are useful to keep a company running. Or, we can say, it includes maintaining inventories to continue manufacturing the end product. For example, it includes keeping inventories of spare parts, tools, equipment, and more.

A company usually maintains the stock of raw materials. However, nowadays, it has become equally important for companies to keep an inventory of spare parts of machines and other things to keep the production running. It ensures that in the event of a breakdown, or any need for a spare part, it is quickly available.

Keeping stock of such things ensures that the production continues smoothly, a breakdown can be handled easily and quickly, and this eventually helps to bring down the overall cost. Moreover, this will also not stress the entire production and logistics system.

MRO Inventory – What it Include?

MRO items may vary from company to company and industry to industry, but every business has items that can come under MRO. Usually, MRO includes the following items:

Also Read: Types of Inventory / Stock

Repair tools; office supplies; gloves, masks, and other safety equipment; laboratory equipment; cleaning or janitorial supplies; batteries; valves, compressors, motors, belts, and more.

Importance of MRO Inventory

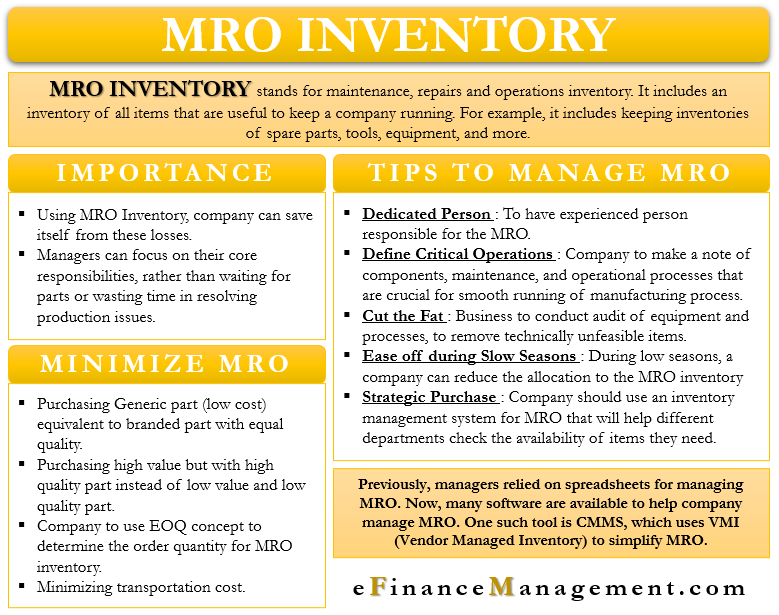

Companies fail to realize the importance of maintaining MRO inventory. A primary reason for this is that this inventory does not directly generate revenue. These inventories usually account for about 5-10% of the total cost of the goods (COGS). It may seem significant, which is why management tries to avoid such costs. The fact, however, is it could help the company save much more than this cost in the long run.

If the production department runs out of a chemical or a tool that is important to keep the machinery running? It could thwart the production, resulting in significant losses both in terms of revenue, manpower, and operational cost.

In another case, suppose a company runs out of the safety item. In this case, the employees may stop working, which could endanger people’s lives. It, again, would result in significant losses for the company. Or, in the worst-case scenario, if they are asked to work in the absence of such safety equipment. Then their lives are put at stake, as well as the regulatory violation.

In both these cases, a company can save itself from these losses by maintaining MRO. Additionally, with proper MRO, the managers can focus on their core responsibilities rather than waiting for the parts or wasting time in resolving production issues.

Thus, to save millions in the long term, a company needs to invest in MRO inventory. Also, just investing in the inventory is not enough; a company must properly manage its MRO inventory as well. It is a one-time affair. Like other inventory items, they also need to be monitored, and most importantly, their ready usability should be checked regularly because some items may have an expiry or may require symbolic operations at the end of every period.

How to Manage MRO Inventory?

The following are the tips to manage MRO Inventory effectively:

The following are the tips to manage MRO Inventory effectively:

- Skilled and knowledgeable Person

One critical point to successfully manage the MRO inventory is to have an experienced person responsible for the MRO. This person should have the technical knowledge across all products, production processes, and equipment that a company deals in.

- Define Critical Operations

A company must first understand and make a note of components, maintenance, and operational processes that are crucial for the smooth running of the manufacturing process. Based on this, it must prepare a list of critical items and their frequency of use. Then, it needs to prepare a replenishment cycle to ensure there is never a shortage of any of the critical components.

- Check on Resources & Technology

A business must regularly conduct an audit of the equipment and processes. The audit will tell the items that are not generally in use or are technologically unfeasible, or are taking up a large number of resources. The company can then remove such items from the MRO inventory.

- Determining Sale Season

A company must use tools to determine the time when the sale is high and when the sale is low. Low sales would mean low production as well. So, during low seasons, a company can reduce the allocation to the MRO inventory as well.

- Purchase Strategically

Different departments may be using the same MRO item. But due to a lack of communication between the departments, they may be unaware of this. And thus, order those parts separately. In such a case, a company should use an inventory management system for MRO that will help different departments check the availability of items they need. Moreover, the system will help the company know the total demand of the items, and thus, could better negotiate with the suppliers, and frequent ordering can also be avoided.

CMMS Software and MRO Inventory

Previously, the managers relied on spreadsheets for managing MRO. Now, many software is available to help a company manage the MRO. One such tool is CMMS, which uses VMI (Vendor Managed Inventory) to simplify MRO.

Under VMI, it is the responsibility of the vendor to maintain the inventory at the level that the company wants. VMI is common with manufacturing companies, but most companies use VMI for a portion of their inventory.

In VMI, the vendor creates a storage area at the client’s location. The production team takes the items as and when they need them, and the vendor then replenishes the inventory to a specific level. The vendor then bills the client based on the number of items removed from the inventory.

The following are the benefits of using CMMS:

- It helps to save time in locating the parts.

- It ensures that the critical items are in stock all the time. Thus, it also helps to avoid ordering extra components.

- The company gets a full report on the items or parts that are being used the most and that are used less.

- It gives all the information on the cost, volume, and frequency of the orders.

- It helps to improve the overall production efficiency.

How to Minimize MRO Cost?

There are a few tips that can help a business minimize MRO costs:

Brand Name vs. Generic

Similar to pharmaceuticals, the generic parts in the manufacturing business also cost less than the parts from well-known firms. Thus, the person responsible for MRO should focus on the specifications of the part. This way, the manager can buy a generic part that meets their need and equivalent of quality and per.

Quality

A part that costs less may be appealing, but it may not be of the best quality. For example, a belt for a machine costs $200, but it works for two months, but another belt that costs $500 would work for a year. Thus, in this way, the company can go for an expensive belt that will result in savings over time.

Economic Order Quantity

For MRO also, the company should use the EOQ (Economic Order Quantity) concept. Such an approach will help the company to save on ordering and storing costs. This way, the company will order the quantity it needs and the quantity that minimizes the ordering cost.

Transportation

Minimizing the transportation cost also helps a company to reduce its MRO cost. A company must regularly audit the current transportation option and search for new ones so that it never misses an opportunity to reduce the cost.

Final Words

MRO inventory has become unavoidable for any business. However, many companies still avoid this until it gets too late. Yes, it does require investment, but its benefits far outweigh the cost. A business can also minimize the investment in MRO by using proper inventory management.

You may like reading – Types of Inventory / Stock.