What is Buffer Inventory / Stock?

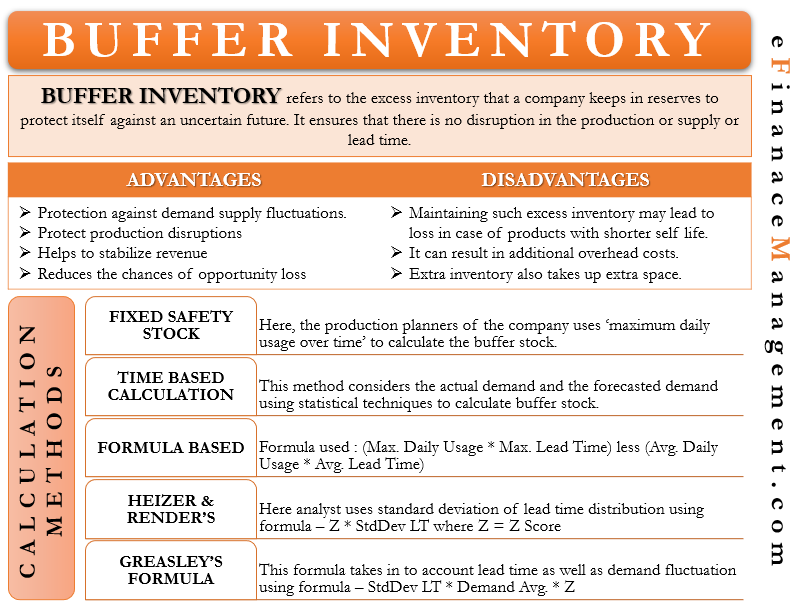

Buffer Inventory is the extra stock of either raw material or final product a company maintains as a protection against unforeseen circumstances. In simple words, we can say it is the excess inventory that a company keeps in reserves to protect itself against an uncertain future.

A company keeps this stock either in transit or at hand to ensure there is no disruption in the production or supply, or lead time. We may also call such a stock as strategic stock, safety stock, or buffer inventory.

A company may apply the concept of buffer inventory at all levels of the supply chain. The main objective is to ensure that production or sales don’t stop.

Advantages of Buffer Inventory

The following are the advantages of maintaining buffer inventory:

- Help to protect against fluctuations in the demand and supply

- It helps to preserve any disruption in production.

- It also helps to stabilize the revenue for the company.

- Such a stock also reduces the chances of opportunity loss as the company has stock to take new orders.

Disadvantages of Buffer Inventory

The following are the disadvantages of maintaining buffer inventory:

- If the products are perishable or have a shorter shelf life, then keeping the inventory could result in losses.

- Creating and maintaining a buffer inventory can result in additional overhead costs.

- Extra inventory also takes up additional space.

Benchmark – How Much is Enough?

A big question that a company faces is how much of a buffer stock it needs to maintain. The amount of buffer inventory a company maintains may have a material impact on its financial numbers. Maintaining a too-high stock could result in high inventory carrying costs. On the other hand, too little buffer inventory may fail to meet the objective of preserving such stock in the first place.

As such, there is no sure-shot answer to this; instead, the company should try to get the answer to this by their experience. A general guide in deciding the level of buffer stock is to balance the cost of maintaining extra inventory against the disruption in business or production.

However, there are a few methods that could assist in determining the safety stock level.

Methods to Calculate Buffer Inventory

The following are the methods to determine the safety stock:

Fixed Safety Stock

In this, the company takes the help of the production planners. These planners don’t use any formula; instead, they decide on the buffer stock based on maximum daily usage over time. The amount of safety stock remains the same until the planner revises it.

Time-based Calculation

In this, the buffer stock is calculated based on future expectations. Usually, the company determines the stock under this method for a specific period. This method takes into account the actual demand and the forecasted demand using statistical techniques. One drawback of using such a technique is that it does not consider business uncertainties.

Formula-based

One popular formula that many analysts use to calculate the buffer inventory is based on the average safety stock that a company will need in case of a stockout. However, this formula does not consider seasonal fluctuations of demand.

The formula is: (max. daily usage * max. lead time) less (avg. daily usage * avg. lead time).

Max daily usage is the maximum units that a company uses or sells in a day, while max lead time is the maximum time it takes the supplier to deliver. Similarly, average daily usage is the average of the maximum and minimum units that a company uses or sells. The avg. lead time is the average of the maximum and minimum time it takes the supplier to deliver the product or raw material.

Heizer & Render’s formula

Analysts use such a formula in case of high uncertainty on the supplier’s end. It gives a better idea by using the standard deviation of the lead time distribution. Thus, it provides a clearer and more accurate idea about the lead time and frequency of late shipments. However, this formula does not take into account the demand changes.

The formula is Z* 𝜎dLT.

Z here is the Z score, while 𝜎dLT represents the deviation in lead time. Or, we can say that 𝜎dLT is the variation (by degree and frequency) between the average and actual lead time. At the same time, the Z score is how sure you are on the need for safety stock. Moreover, A low Z score would mean you expect higher chances of running out of stock.

Greasley’s formula

Unlike Heizer & Render’s formula, this formula takes into account the lead time and demand fluctuations. This way, it gives an even better idea of the level of safety stock. However, this formula doesn’t consider the stock already in the production process.

The formula is: 𝜎LT * Davg * Z

In this, we multiply the standard deviation in lead time (𝜎𝐿𝑇) with the average demand (Davg) and Z score.

Government Buffer Stock

Along with the business use of the buffer stock, the term is also used in the context of the government’s buying and selling for social good. Usually, the government buys the extra stock of commodities from the market when there is an excess supply. Then it sells them at a time when the supply is less than the expectations.

In this way, the government maintains a buffer stock of the commodities. Such a practice helps to prevent prices from going too low when there is excess supply and rising too high when the supply is less. In all, we can say that it helps to stabilize the prices of essential commodities. It also helps in times of natural crisis to continue the supply of essential items and at reasonable prices.

Advantages

- It assists in regulating the supply of essential food items. In turn, it lowers or eliminates the chances of food shortages.

- It also helps to stabilize the prices and, in turn, encourages more investment in agriculture.

- Another long-term benefit is that it leads to higher employment.

- For the farmers, it protects their income and keeps them safe from the sudden drop in prices.

- For the government, it helps to ensure the social well-being of all. The government also earns a profit by exporting excess food supplies.

- It also helps in times of natural crisis to continue the supply of essential items and at reasonable prices.

Disadvantages

- The government may resort to higher taxes to recover the cost of buying the excess inventory.

- Some items, because of their perishable nature, can’t be stored, such as milk.

- Deciding on the buying and selling price could be tricky as the government does not always get the right data and information.

- If there are implementation issues, it could result in corruption.

- And another biggest issue is proper storage and upkeep. Because of this, a substantial chunk ultimately goes waste.

Also, read Other Types of Inventory/Stocks.