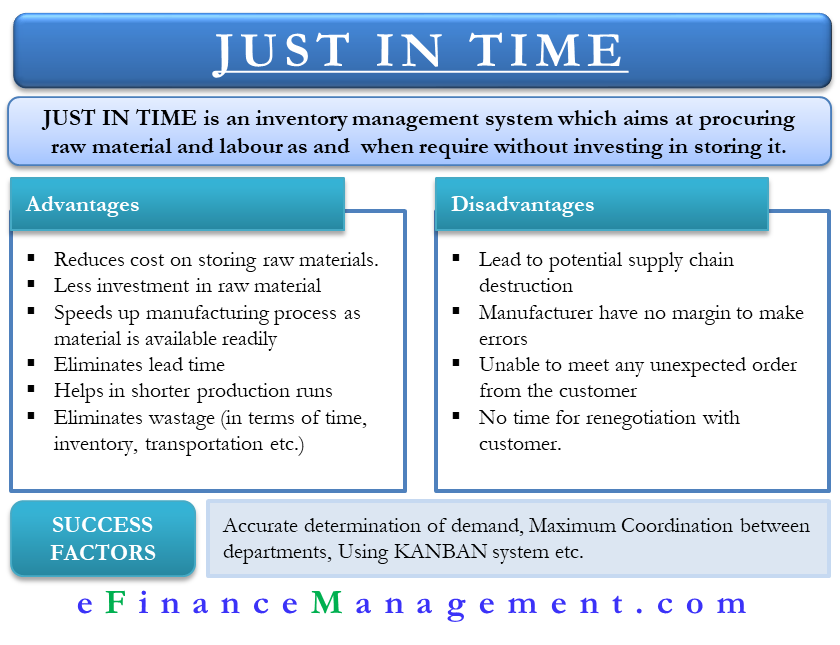

Just in Time (or the JIT) is an inventory management system that aims to make production super-efficient. Under this, the raw materials and labor are planned to arrive as and when needed in the production. The primary benefit of using JIT is that the company does not have to invest time and money to store the raw materials.

Such an inventory management system suits companies with repetitive manufacturing processes, such as most consumer goods companies. On the other hand, JIT won’t be much beneficial to small organizations, hospitals, and other entities.

One can also call JIT as the Toyota Production System (TPS). The Japanese car-maker used it for the first time in 1970. Other companies that use JIT are Apple, Tesla, Zara, Xiaomi, etc.

To know if a company is following JIT or not, one should look at its inventory and asset turnover ratios. A high inventory and turnover ratio would mean that the company is using JIT for managing its inventory. Also, a company with a low inventory balance could be using JIT.

Also Read: Inventory Management Techniques

Let’s understand JIT with the help of an example. Assume ABC Company makes smartphones, and its production schedule includes ‘fitting display’ on Tuesday, ‘processors’ on Wednesday, and so on. If ABC follows JIT, then it will get the delivery of the ‘displays’ on Monday and ‘processors’ on Tuesday.

Advantages of Just in Time

- It helps to reduce the costs as the company does not have to spend on storing the raw materials.

- Companies make less investment in the raw materials as they order the quantity they need to meet the current production process.

- JIT speeds up the manufacturing as the company has the raw materials ready.

- It helps to eliminate lead time and, at the same time, deliveries as well.

- JIT results in shorter production runs. This means that the company can swiftly switch to another product.

- It helps identify and eliminate any obstacles to speed up the production process.

- It helps to eliminate all types of wastage, including time, inventory, transportation, processing, waste from overproduction, and waste from product defects.

Critical Success Factors

The success of JIT depends on several factors, but the most important is that the manufacturer must accurately predict the demand. Only after predicting the demand a company can properly instruct suppliers about the quantity of raw materials it wants. In case the company underestimates the demand, it could lead to losses. On the other hand, overestimation would lead to raw materials lying idle on the factory floor.

Other critical factors to ensure the success of JIT are a commitment from suppliers, no breakdown in the equipment, efficient workers, and a smooth production process. Also, to get the maximum benefit from JIT, a company should ensure maximum coordination between the raw material delivery and manufacturing process.

Apart from these, companies following JIT can use Kanban to make JIT even more efficient. Kanban is a scheduling system that a company can use along with JIT to make further production more efficient. Such a system analyzes the production process, including lead and cycle times, to identify the areas with problems. This, in turn, helps to set inventory limits, thereby avoiding overcapacity.

Also Read: How EOQ helps in Inventory Management?

What about Suppliers?

Companies that use JIT rely on a limited number of suppliers. Since the production schedule is tight, having a small number of suppliers makes it easier to coordinate. Companies following JIT place big orders with the suppliers. This ensures commitment from the suppliers to stick to the delivery schedule and also offers competitive rates.

Disadvantages of JIT

One major disadvantage of this inventory management system is that it could lead to potential supply chain disruptions. For instance, if one of the suppliers fails to deliver the raw materials as per the schedule, it would impact the complete production line. This will install the production, resulting in late delivery or even canceling orders.

For example, Toyota had to suspend production in 1997 for several days after a fire broke out at one of its suppliers. This had a ripple effect as well. Because of this, other Toyota suppliers also had to suspend their production as the automaker did not require their services for the time being. Toyota had to incur a massive loss of about 160 billion yen due to this.

Another disadvantage of JIT is that the manufacturers have no margin to make errors. Any wrong move, such as predicting the demand, or instructing the supplier, would lead to significant losses.

One more drawback of JIT is that the company is unable to meet any unexpected orders from a customer. Also, it could result in lower profits in case the cost of raw materials rises as the company won’t have time to renegotiate with the current supplier or look for another supplier.

Are You Ready for JIT?

If you are planning to implement JIT in your organization, you will have to make thorough preparations. However, even before those preparations, you will have to ensure that your company is prepared to implement JIT. To know this, you will have to ask yourself a few questions. These are;

- The products that you offer, can you produce them in a short period of time?

- Do you have suppliers who are reliable to deliver the raw materials as per the schedule?

- Can you correctly forecast the demand and know about seasonal fluctuations that your business faces?

- Is the current inventory management method inefficient?

- Will you be able to increase profits by using JIT?

After you have got the answer to the above questions, = follow the below principles to effectively implement JIT;

- Make efforts to lower buffer inventory.

- Aim for zero inventory.

- Make efforts to reduce the order size while raising the frequency of orders.

- Focus on lowering the purchase cost and improving material handling.

If you don’t want to use JIT, then an alternative could be MRP or the “materials requirements planning” system. It is also a push inventory system like JIT. The “push” concept means that the company must have raw materials in the store to push it to the production floor. MRP system is best for an organization that can correctly predict the sales of its products.

Final Words

Just in time was developed in Japan, but it is now in use in most parts of the world. Moreover, it has inspired several other inventory management systems, such as IBM’s Continuous Flow Manufacturing (CFM). You must make thorough preparations and proper planning to implement JIT in your company.

Keep reading about other types of Inventory Management Techniques.

good infrmation